- Home

- >

- News

- >

- Industry News

- >

- Characteristics of The Shell-and-Tube Heat Exchanger

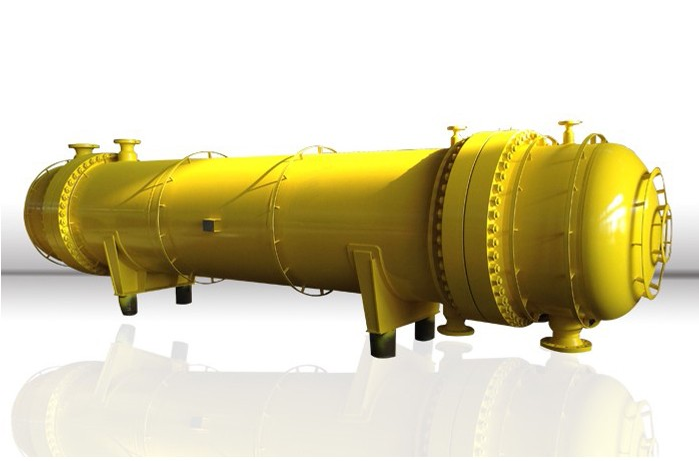

Characteristics of The Shell-and-Tube Heat Exchanger

The characteristics of the shell-and-tube heat exchanger are that the heat exchange area provided by the unit volume equipment is much larger and the heat transfer effect is also good. He has become a typical heat exchange equipment used in chemical production for a long time.

Shell-and-tube heat exchangers have fixed tube plate steam-water heat exchangers, expansion tube shell-type steam-water heat exchangers, floating head steam-water heat exchangers, U-shaped shell-and-tube steam-water heat exchangers There are several types of corrugated shell-and-tube steam-water heat exchangers and segmented water-water heat exchangers. The main control parameters of the shell-and-tube heat exchanger are heating area, hot water flow, heat exchange amount, and heat medium parameters.

Classified by product application

Divided into coolers, heaters, condensers, vaporizers and heat exchangers.

Classified by material used in heat exchangers

Generally, the heat exchanger can be divided into metal materials and non-metal materials, and the metal materials include: stainless steel, titanium, nickel, carbon steel and other metal materials.

Classification of heat transfer surfaces according to the shape and structure of heat transfer weapons

Heat exchanger through heat transfer through the pipe wall

Heat exchanger through plate heat transfer

Bellows heat exchanger

Other forms of heat exchanger

Shell and tube heat exchanger

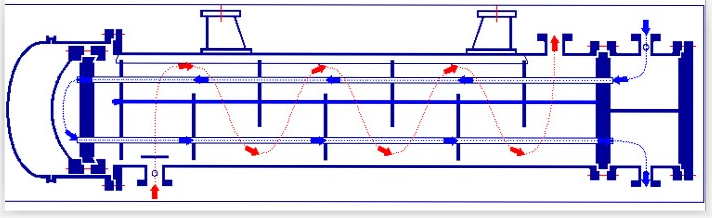

He is currently the most widely used heat exchange device and serves as a standard heat exchange device. It is a bundle of tubes consisting of a number of tubes that are attached to the tubesheet and the tubesheet is coupled to the outer casing. In order to increase the flow rate of the fluid in the off space to improve his heat supply, a plurality of baffles are installed at intervals in the cylinder. The end of the heat exchanger and the end caps on both sides are provided with fluid inlet and outlet, and sometimes an inspection hole is installed thereon, an interface for measuring instruments, a discharge liquid and a vent hole. The heat exchanger is characterized by easy manufacture, low production cost, wide selection of materials, convenient cleaning of the heat exchange surface, strong adaptability, large processing capacity, and application under high temperature and high pressure.

Hot spot of shell-and-tube heat exchanger

1. High efficiency and energy saving, the heat transfer coefficient of the heat exchanger is 6000-8000W/m2.0C.

2. All stainless steel production, long service life, up to 20 years.

3. The layered flow is turbulent, which improves the heat exchange efficiency and reduces the thermal resistance.

4. Fast heat exchange rate, high temperature resistance (400 °C), high pressure resistance (2.5Mpa).

5. Compact structure, small footprint, light weight, convenient installation and saving civil construction investment.

6. Flexible design, complete specifications, practical and targeted, saving money.

7. Wide application conditions, suitable for large pressure, temperature range and heat exchange of various media.

8. Low maintenance cost, easy operation, long cleaning cycle and convenient cleaning.

9. Using nano-thermal film technology, significantly increase the heat transfer coefficient.

10. It has a wide application field and can be widely used in fields such as thermoelectricity, factories and mines, petrochemicals, urban central heating, food and medicine, energy electronics, and mechanical light industry.

11. The heat transfer tube adopts a copper tube with fins on the outer surface, which has high thermal conductivity and large heat exchange area.

12. The deflector guides the shell-side fluid to flow continuously in the shape of a line in the heat exchanger. The spacing of the deflector can be adjusted according to the optimal flow rate. The structure is firm and can meet the large flow rate or even the large flow rate and the high frequency of the shell flow. Heat exchange.

13. When the shell side fluid is oil, it is suitable for heat exchange between low viscosity and clean oil.