- Home

- >

- Products

- >

- Station Equipment

- >

- Filter Separator

- >

- Three Phase Filter Separator

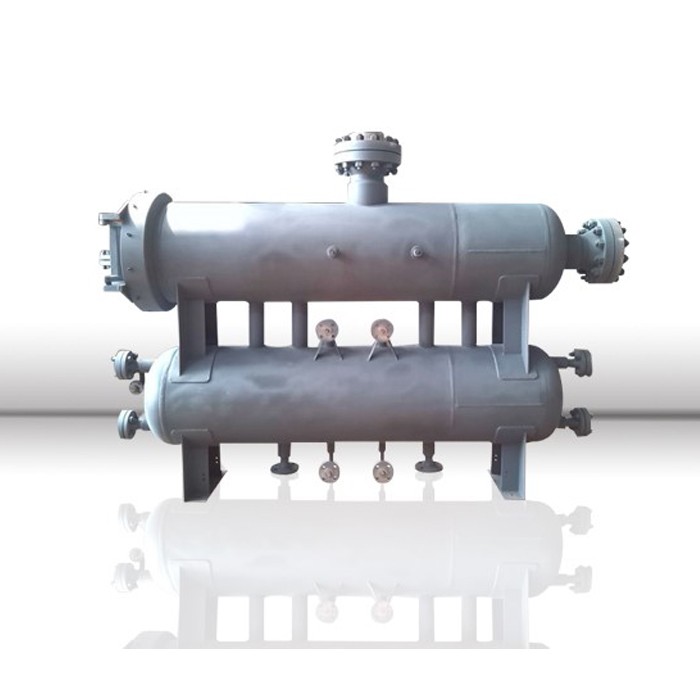

Three Phase Filter Separator

Brand :YY

Product origin :LIAONING,CHINA

Delivery time :Normally 30~60 days after order award

Supply capacity :10 pieces per month

Oil gas water three phase separator is one of the most commonly used equipment in oil field development and production. A "solid, liquid and gas" three-phase separation device installed in the oil well of the oil field under the pump.

Oil gas water three-phase separator working principle

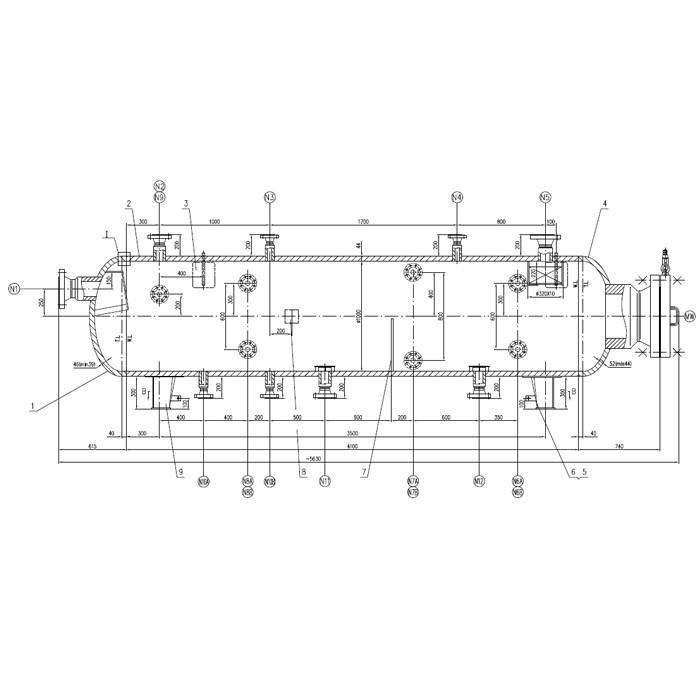

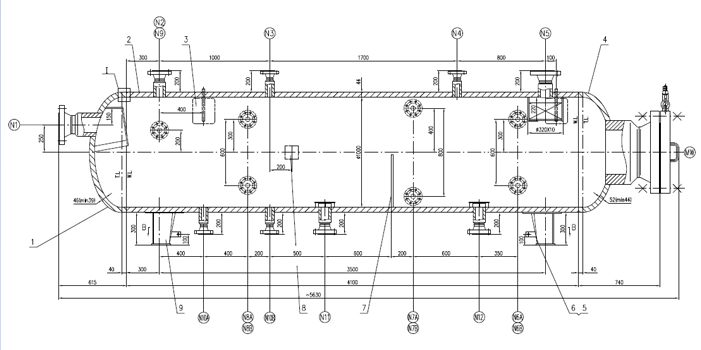

Oil gas water mixture in high speed into the pre degassing chamber, by separation and gravity from the massive oil associated gas, oil water pre degassed mixture by high-speed diversion pipe into the distributor and washing room, in water containing demulsifier activity in demulsification of washing, steady, low drop Reynolds coefficient to liquid, followed by coalescence after rectification, flowing into the separation chamber further separation, crude oil over the diaphragm into the oil chamber, and the flow meter, after controlling the outflow of water separator by pressure balance catheter into the water chamber, so as to achieve the purpose of oil gas water three phase separation.

Quick Details

| Condition: New | Brand Name: YY-FS |

| Type: Separating Plant | Model Number: YY-FS |

| Product Type: Petrochemical | Voltage: As Request |

| Power(W): Normal standard | Flowchart Design: Available,Rigid |

| Weight: Customized | Materical Code: From ASME & ASTM |

| Dimension(L*W*H): Customized | Flange: ASME.B.16.5, B.1647 |

| Production Capacity: 99.9% | Design Code: ASMEVIII-I |

| Manner: According to customers' specifications | Certification: ISO 9001-2008 |

| Warranty: One Year Excluding Spare Parts | Place of Origin: Liaoning, China (Mainland) |

| After-sales Service Provided: Engineers available to service machinery overseas | |

Characteristics of three phase separator

Interface controller and weir plate: does not apply to heavy oil or a large number of emulsion or paraffin.

Tank and weir design: the requirements of the water weir plate should be placed below the oil weir plate a distance.

| Design Code | ASME VIII-1 |

| Design Pressure | Up to 16 Mpa |

| Precision | 0.5~100um |

| Filtration Efficient | 99.99% |

| Diameter Range | DN15~DN1000 |

| Core Material | Stainless Steel |

| Main Body | Carbon Steel & Stainless Steel |

| Widely Used | Refiner,Petrochemical,Chemical and so on |

Type of three phase separator

General three-phase horizontal separator

The internal structure of the gas-liquid mixing fluid gas-liquid separator inlet into the basic phase separation, and after rectifier and gravity gas into the gas passage, isolated droplets.

The liquid into the liquid space separated bubble oil flow upward and downward flow of water in the gas separation, leaving the separator before mist eliminator removes small droplets from the outlet of oil outflow from the top through the overflow baffle into the oil tank and flows out from the outlet, water overflow baffle into the tank and flows out from the outlet.

Three phase vertical separator

The gas-liquid mixing gas-liquid fluid inlet into the separator through mutation of the velocity and direction of the basic completion of phase separation.

Gas flow upward in the gas passage through gravity sedimentation separation of liquid droplets.

The downcomer enters the oil-water interface, air bubble and oil upward flow of water flowing down to the separation.

Performance of coating technology in general, corrosion resistance is often more than the same temperature resistant and wear resistant coatings, and these are compared to other coatings system.

Packaging & Shipping

Packaging Details: Bulk

Delivery Detail: According to the quantity ordered Specifications

After-sales service

We promise that:

We answer and solve your questions and consult within 24 hours.

We arrive to the domestic job site within 48 hours from the time you asked.

Overseas job site service available.

Service telephone: +86-24-88256563